Imagine navigating a world where identification numbers didn’t exist. Without bank account numbers, driver’s license numbers, and social security numbers, it would be nearly impossible to look up information about a specific person with 100% certainty that you’re not mixing up people with the same name.

Shouldn’t every piece of furniture, fixture, and equipment (FF&E) in your commercial space require the same standard?

When designing and building commercial spaces, its inevitable that teams will need to cross-reference information between resources, whether it be spreadsheets, databases, construction drawings, or software as it is highly unlikely that all information about anything is stored in one place.

That’s why an identification system is critical for assets — it unlocks the ability to use an ID as a key to reference across all data sources.

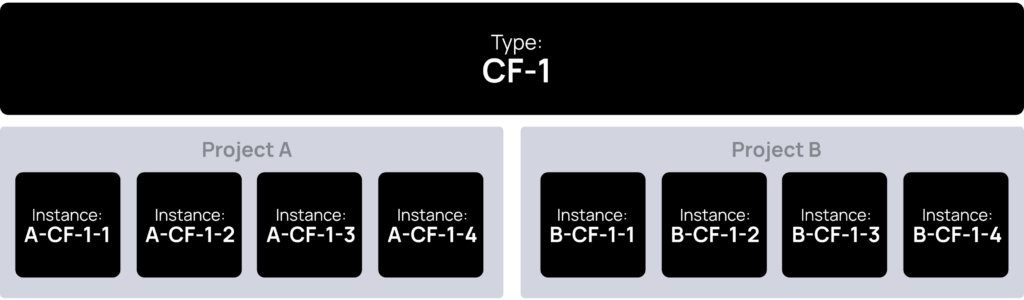

Technically, there are two types of asset IDs.

Type ID: Assigned at the program level (not project level) to each type of an FF&E across an entire program. This is useful for design, procurement, and construction processes as it can be assigned to a type of fixture with a specific combination of options.

Instance ID: Assigned at the project level to each instance of an FF&E in any given project. This is useful for facility management and operational processes because it is typically used to track each physical asset’s information such as its location and maintenance history.

For this post, we’ll focus on the Type ID.

Why do we need a type ID?

Yes, it is possible to look up a piece of furniture, fixture, or equipment simply by referring to its manufacturer and model, but sometimes that just isn’t unique enough. Manufacturers will often use a single model name to encompass several variations of an asset’s form, fit, and finish. When this is the case, their customers need to create their own methods to track those variations — this is where a type id applies.

Let’s look at some examples of where manufacturers do not provide a unique model name and would require a design team to come up with their own type ID.

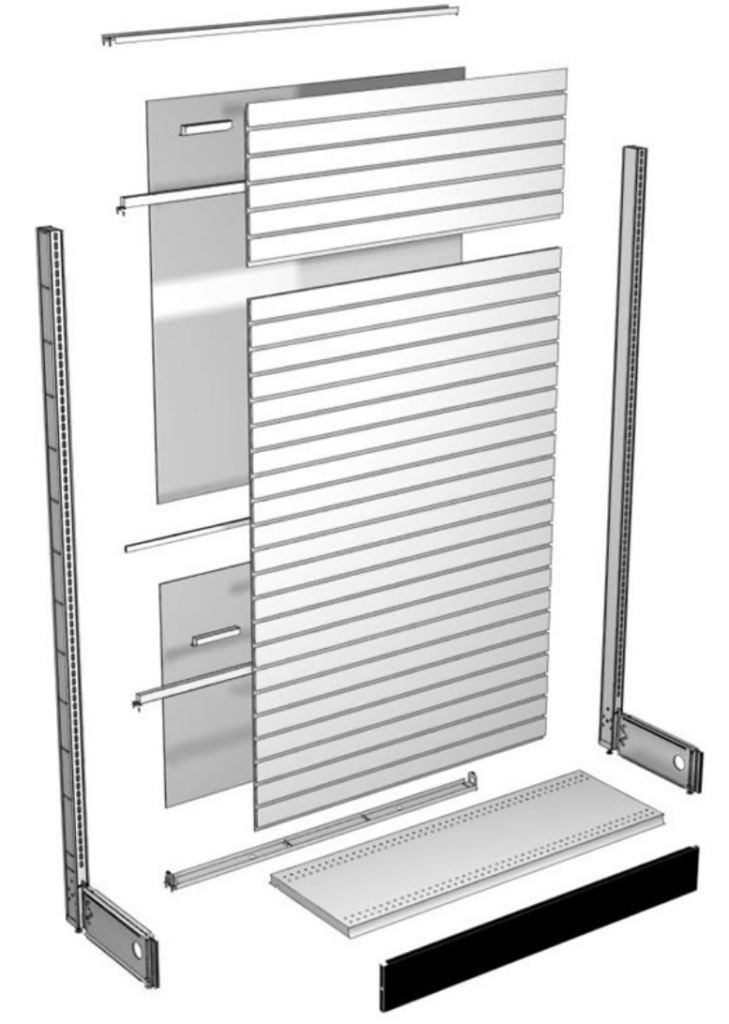

1. Complex fixtures with several accessories leave behind a puzzle to be pieced together.

Some retail display fixtures have so many optional parts and accessories that manufacturers simply can’t provide an overarching model number for every possible combination.

The image below is an illustration of a Lozier shelving unit. Believe it or not, all of these pieces combined do not have a single model number to tie them all together; only the individual parts have their own part numbers.

Do all of these parts and pieces need to be listed on a set of construction drawings? Let’s hope not. If not, how does the procurement team ensure the correct parts and pieces get shipped to the job site for construction?

A type ID would help tremendously here. For example, if we assigned A-001 as the type ID to this assembly, the design, procurement, and construction teams would know that every instance includes the (2) uprights, (1) back panel, (1) base deck, etc.

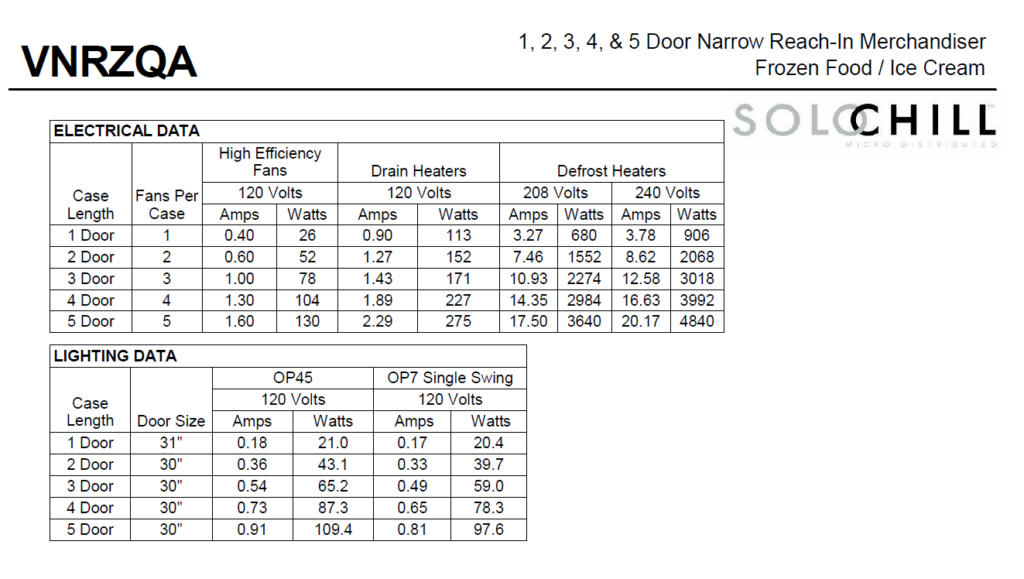

2. Same model number, different sizes.

In this example, we see that Hill Phoenix produces an entire line of freezers for physical retail stores under the model name VNRZQA. That’s right, a single model number for five different sizes of a fixture.

Sure, one could find an instance’s size by reviewing drawings or measuring the physical fixture on site, but that is time-consuming, opens up risk for error, and technically blocks automation tools from using VNRZQA as a unique identifier.

This is where a type ID is helpful. Although all five fixtures have the same model name, they could each be assigned a unique type ID like so:

F-001: Hill Phoenix: VNRZQA : Freezer – One DoorF-002: Hill Phoenix: VNRZQA : Freezer – Two DoorsF-003: Hill Phoenix: VNRZQA : Freezer – Three DoorsF-004: Hill Phoenix: VNRZQA : Freezer – Four DoorsF-005: Hill Phoenix: VNRZQA : Freezer – Five Doors

This removes any guesswork on which specific size of the VNRZQA is used in a particular project as it can be shown in construction drawings or even on labeled on the physical asset in store.

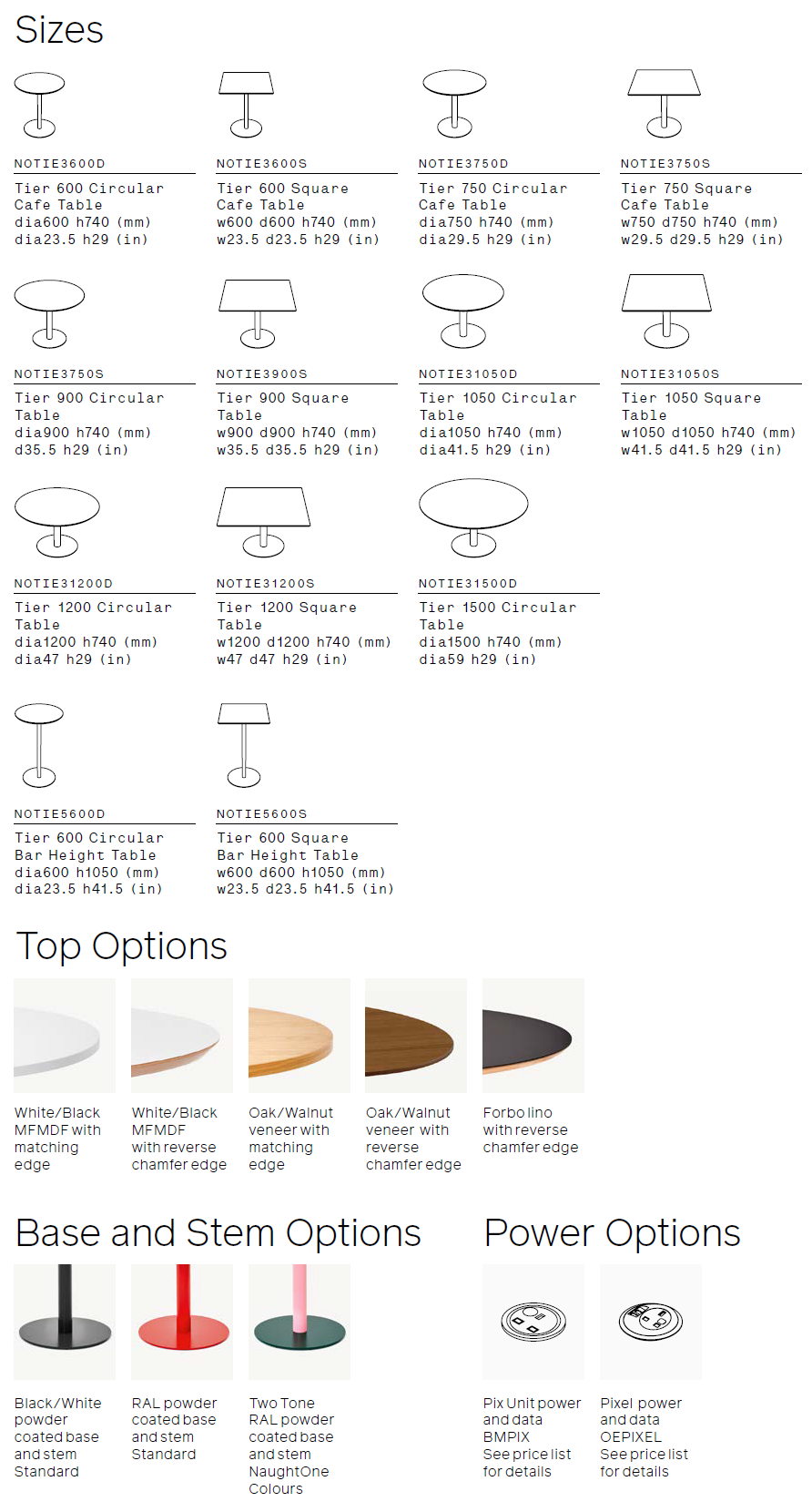

3. Sizes, shapes, and bases… Oh my!

Another common example of where manufacturers often do not provide a unique model number is for tables. Manufacturers often provide several options to enable designers to customize the size, shape, and finish of a table, and it would be complicated for the manufacturer to provide a model number for each and every combination.

Below is the spec sheet for the Tier table by NaughtOne. When specifying this table for a project, a designer will immediately find themselves confronted with several options.

Based on the above options (plus color options not shown), there are over 6,000 possible combinations for the Tier table, and that’s not including the two-tone color options for the bases!

Although not impossible, it would be difficult for design and procurement teams to track even just a few configurations. Imagine trying to identify two different 600mm circular tables on a floor plan when they are different heights or finishes — they look exactly the same in plan view.

A type ID would eliminate the guesswork by identifying a specific combination of options per ID. This ID would be tagged on floor plans as a way to cross reference between the construction drawings and other resources.

I won’t list all 6,000 possible configurations, but here are just a few examples of how this product line could be broken out:

F-001: NaughtOne : Tier : Circular – White – 600mm – Black BaseF-002: NaughtOne : Tier : Circular – Walnut – 600mm – Black BaseF-003: NaughtOne : Tier : Circular – Black – 750mm – Black BaseF-004: NaughtOne : Tier : Circular – Black – 900mm – Black BaseF-005: NaughtOne : Tier : Square – White – 600mm – Red Base

Just like the Hill Phoenix freezer, the type ID system enables teams to identify a specific configuration of a table.

Ok, I’ve got my type IDs assigned to my assets. What’s the best way to manage them?

Understandably, many organizations will default to spreadsheets as a way to organize their assets. Whether it’s Excel, Smartsheet, Airtable, or other, these solutions do not scale well for asset information management.

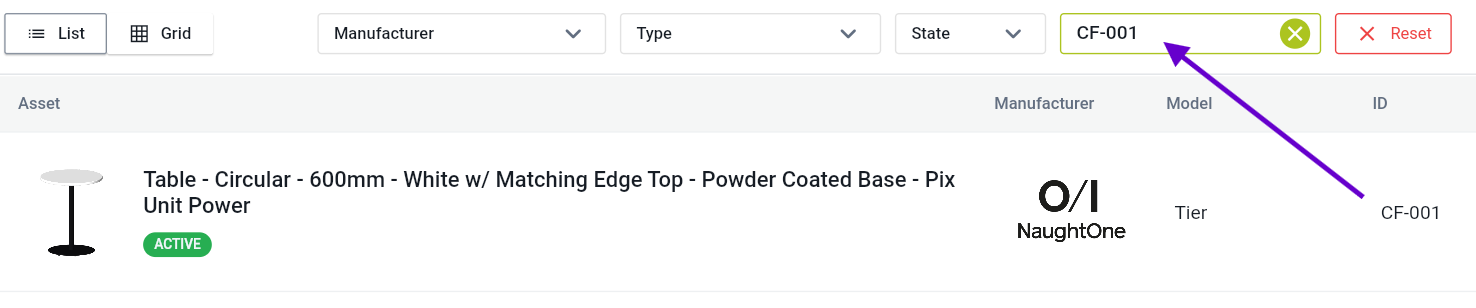

At its core, Ephany offers a user-friendly way to organize your entire database of furniture, fixtures, and equipment (FF&E). Finding the exact configuration you need is effortless — Simply search by type ID , manufacturer, model, or any keyword to pinpoint a specific FF&E in seconds.

Let’s look at what the the collection of Tier tables would look like in Ephany.

type ID.Drilling down into an asset reveals metadata for each asset, making it easy to find key information like dimensions or links to the manufacturer’s website.

Here’s where Ephany helps manage asset catalogs which leverage the type ID strategy.

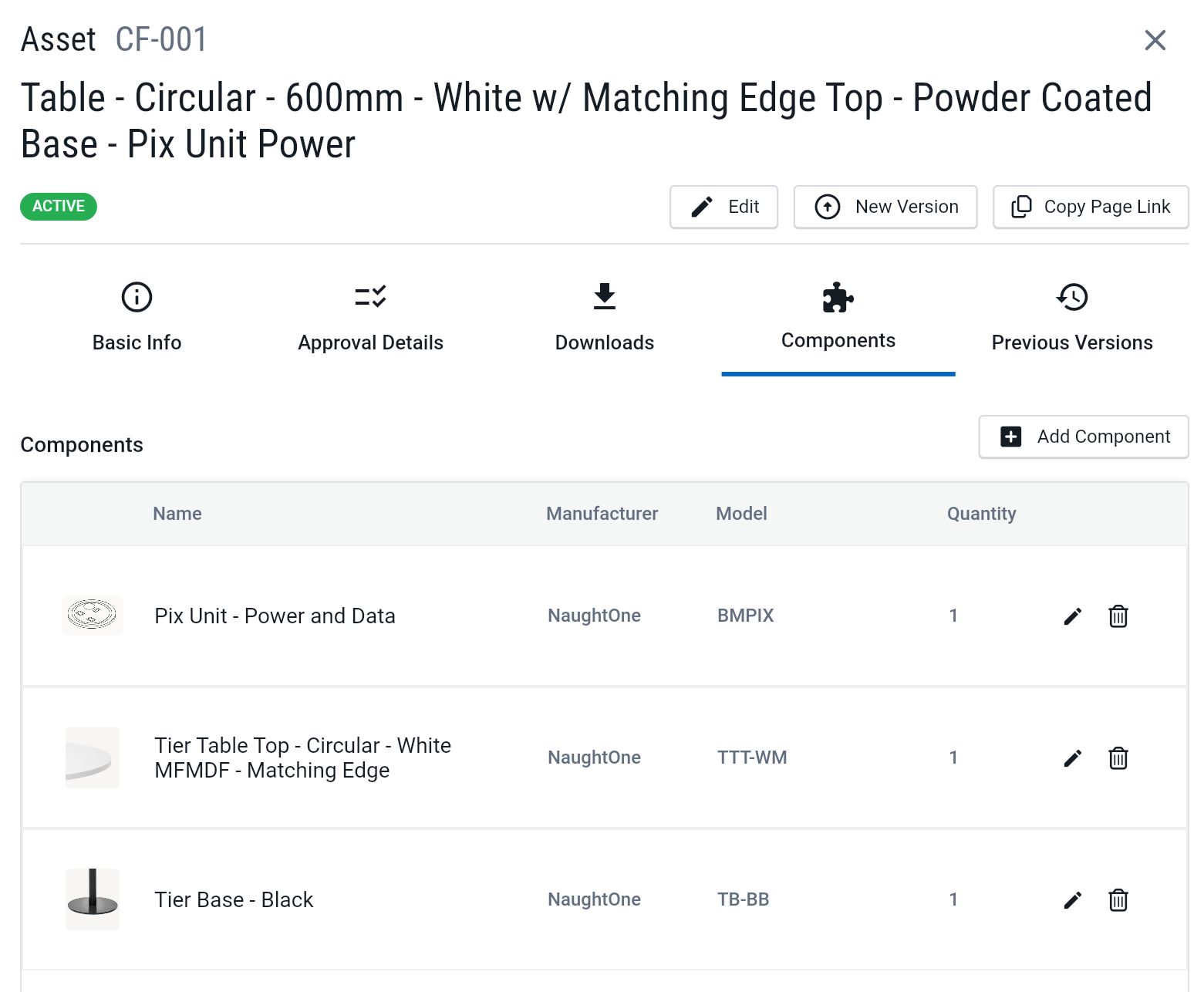

In addition to the typical asset information, any given asset can be broken out into individual components. Using the CF-001 table as an example, we can see that every part that makes it up can be listed with the asset (including quantities) which makes it easy for a team to know exactly what parts make up the specific configuration for this type ID.

This of course can be rolled up into the project view which calculates the total components in a bill-of-materials (BOM).

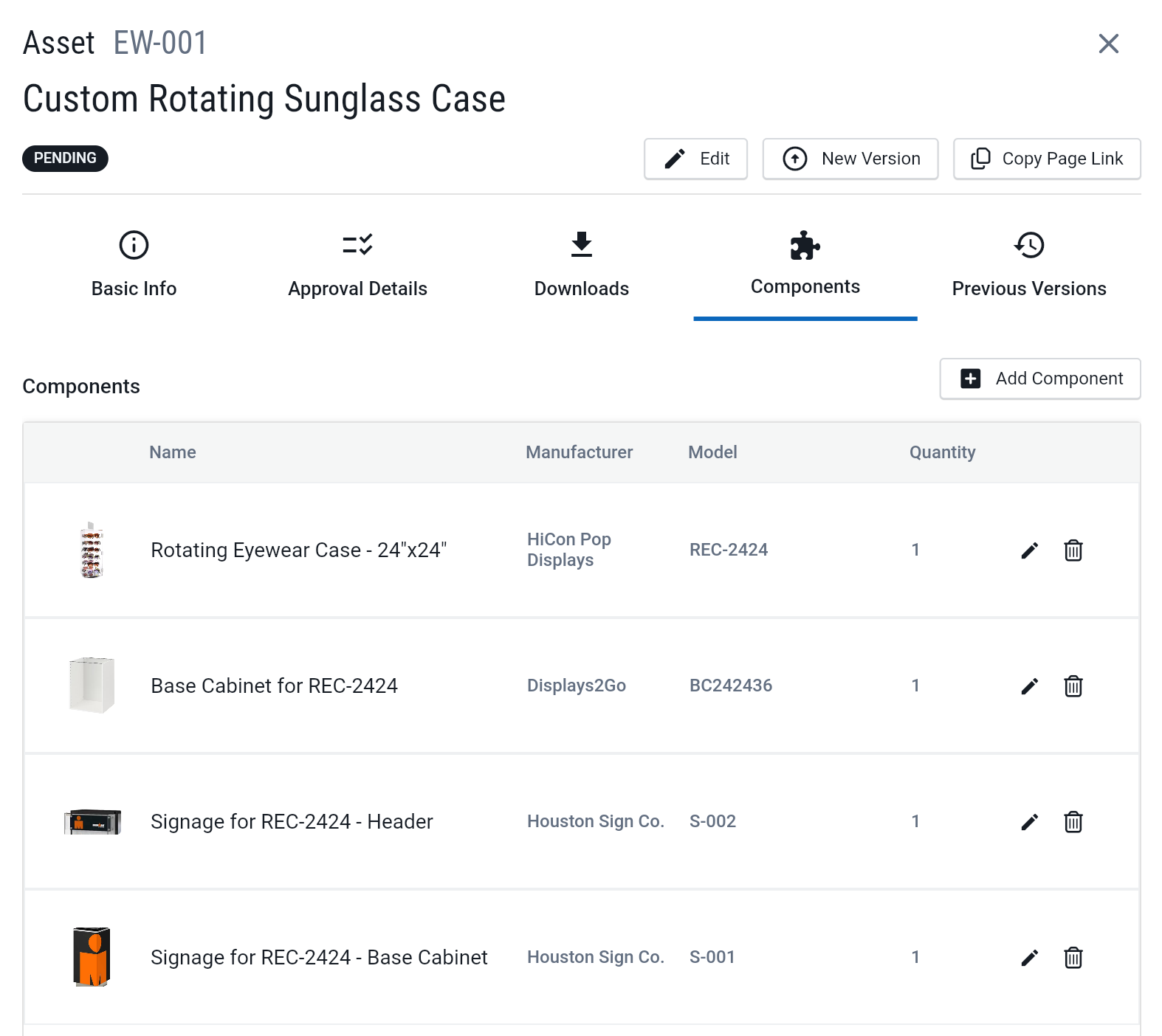

Fun fact: Ephany can even track components which come from multiple manufacturers as shown below. This simplifies procurement processes for even the most complex fixture designs.

Conclusion: Ephany is next-level asset planning.

In conclusion, Ephany takes the process of managing a catalog of furniture, fixtures, and equipment (FF&E) to the next level by not only enabling teams to track each asset by its type ID, but also by creating relationships to each individual component that make each asset unique. Whether it’s a custom table with multiple finishes or a retail display fixture with specific accessories, Ephany ensures every part is accounted for and tied together seamlessly. This holistic approach keeps your teams aligned, minimizes mistakes, and saves time across projects.

Ready to see it in action?

This is just one way Ephany helps teams with improved their approach to implementing FF&E across repeatable designs. Reach out to schedule a live demo and discover how Ephany can simplify your asset information management processes.